MWG Series

Pipe/Pipe TIG Welding

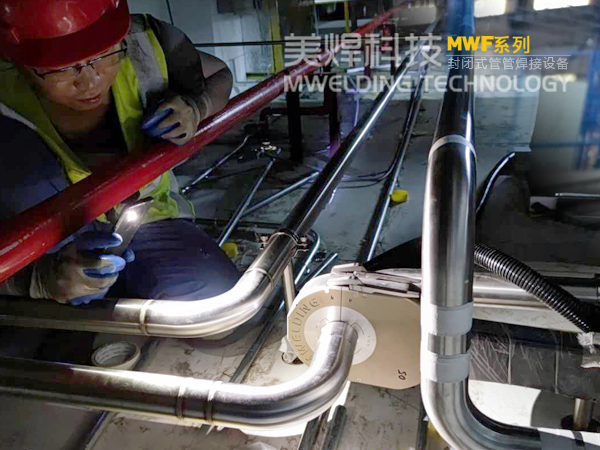

Open Pipe-to-Pipe Welding Equipment: Unlock Medium-thick Wall Pipe Welding

Welding Parameters

Welding Range: 32-325mm

Weldable Wall Thickness: 1-25mm

Welding Posture: All-position Open Type

Welding Forms: Various joints (pipe-to-pipe, pipe-to-elbow, etc.)

Welding Materials: Stainless steel, carbon steel, nickel-based alloy, etc.

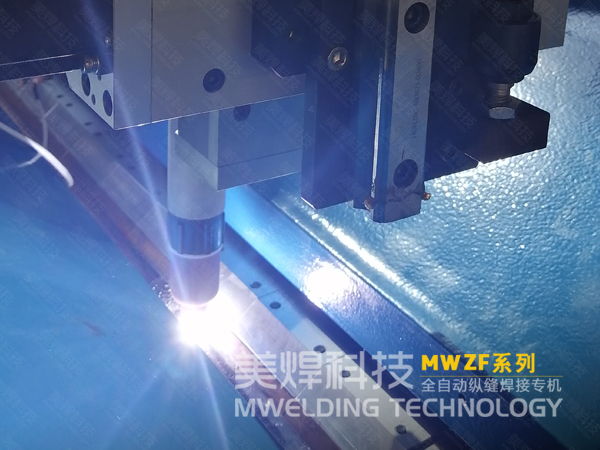

V-groove design, single-sided welding with double-sided forming, meeting radiographic inspection requirements

The MWELDING MWG Series features an open welding head design, with a dedicated torch tailored for pipe/pipe TIG welding. It adapts to general autogenous or wire-fed automated welding.

MWELDING MWG Series Pipe-to-Pipe Welder

Medium-thick Wall Pipes Handled Effortlessly

Precision Welding

Caliper-type clamping allows free adjustment for different pipe diameters

Optional wire-filling or autogenous welding modes

Automatic arc length adjustment with weaving function

Suitable for multi-pass welding process requirements

Precision Technology: Mainly applied to pipe/pipe TIG welding in industries like engineering installation, petrochemicals, energy & power, boilers, nuclear power/military.

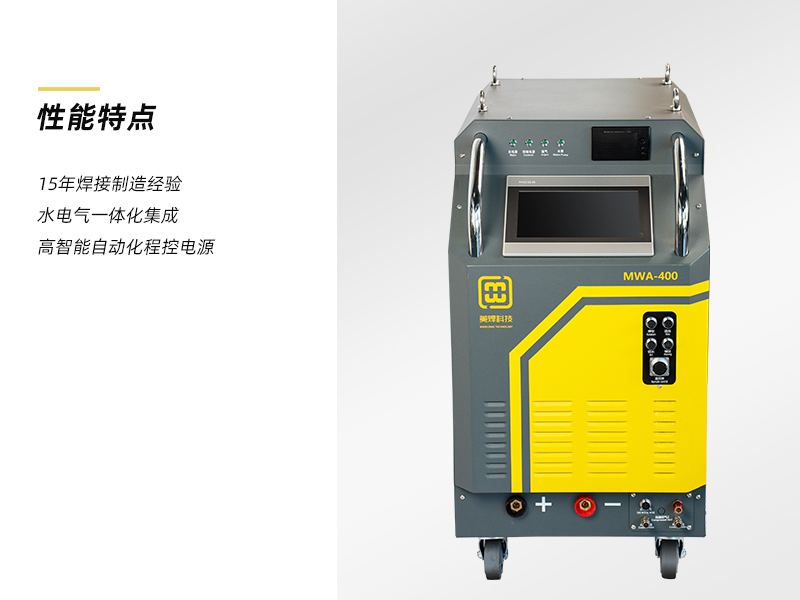

MWELDING MWA-400 Integrated Welding Control Power Supply

Suitable for Open Welding Clamps on Thick Wall Pipes

Intelligent Control

The MWELDING MWA-400 welding power supply is an automatic program-controlled unit designed & manufactured with world-leading TIG welding technology. When paired with MWELDING MWG Series open welding heads, it enables high-precision thick-wall pipe-to-pipe welding.

Process Advantages of MWELDING MWG Series Open 360° Pipe Welding System:

Fully emulates the welding techniques of master craftsmen

MWELDING intelligent welding control system: real-time efficient control ensures welding stability and reduces manual intervention

Attractive weld formation and reliable quality

Complies with industry-standard V-groove welding, adapting to on-site conditions and relevant industry standards

Allows spot welding gaps to facilitate back protrusion

Adapts to 0-1mm misalignment, with low assembly requirements

Welding efficiency increased by over 100%

Combines forward and reverse welding (per process needs) to reduce idle time and optimize weld formation

Fast welding speed + large filling volume; pulse welding for root pass, filling and capping reduces heat input, ideal for all-position welding processes and quality

15 years focused on the welding industry

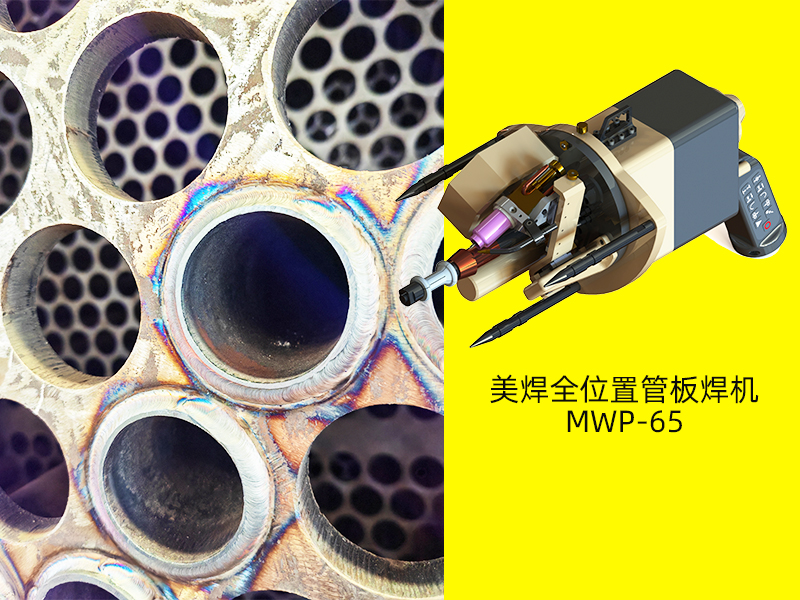

Pipe-to-pipe welding / Pipe-to-plate welding / Special welding machines / Robots

Intelligent welding solutions