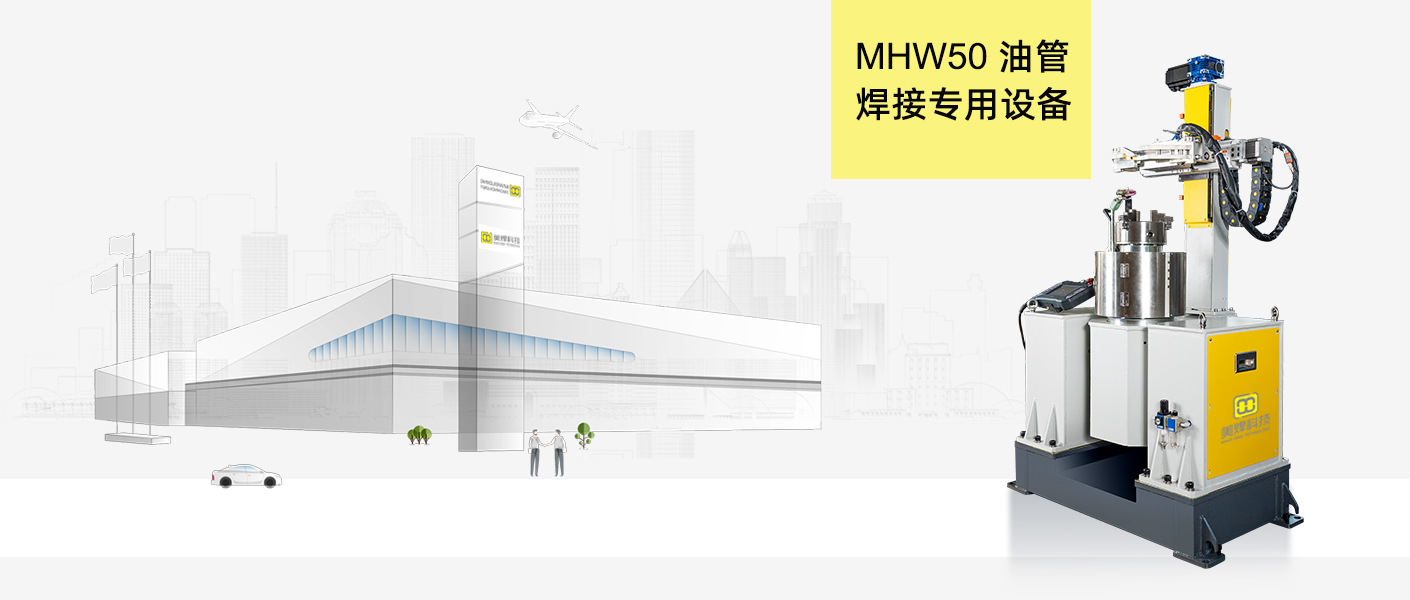

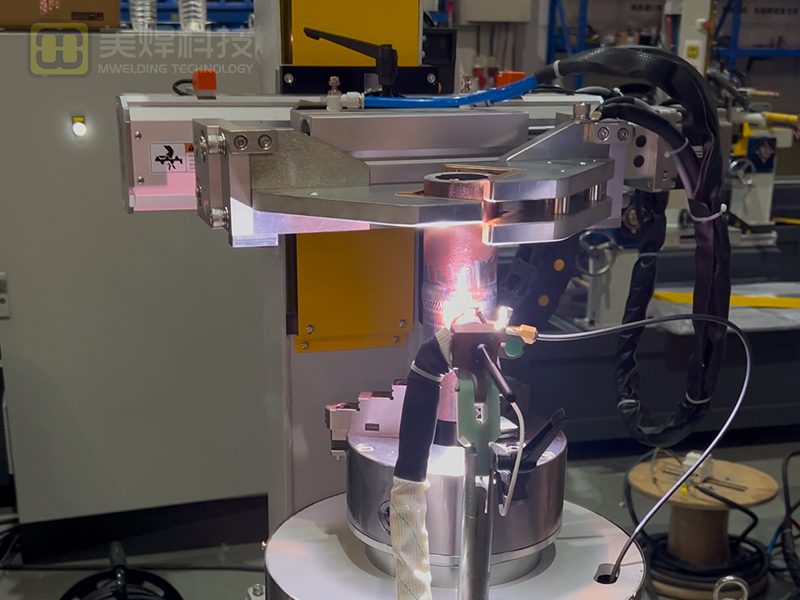

In the manufacturing of oil pipes in the automotive, construction machinery, and hydraulic system fields, the precision and efficiency of circumferential seam welding directly determine product reliability. The MHW50 automatic oil pipe circumferential seam welding machine launched by Shanghai Meihan Technology takes fully automatic TIG welding technology as its core, integrates high-precision control and humanized design, and has become a preferred equipment for oil pipe circumferential seam welding, providing a stable and efficient solution for industrial production.

I. Application Scenarios and Core Parameters of the Equipment

The MHW50 welding machine is tailor-made for oil pipe circumferential seam welding, with a wide range of applications and flexible parameter configurations. It can weld workpieces with a diameter ranging from φ10 to φ80mm, a maximum length of 3000mm, a wall thickness ≤9mm, and a maximum load capacity of 50kg. It can meet the welding requirements of various connection forms such as pipe-pipe and pipe-flange, and is compatible with materials such as carbon steel and stainless steel.

The equipment is suitable for harsh industrial environments, with an operating temperature range of -10℃ to 45℃, a relative humidity ≤85% (non-condensing), and can operate stably in a three-phase 380V±10% voltage environment below 1000m above sea level. The welding process adopts filler wire TIG welding, combined with industrial pure argon shielding gas, to achieve a full-penetration structure and single-sided welding with double-sided forming. The weld reinforcement is ≤1.6mm, without defects such as undercut and cracks, meeting high-precision welding standards.

II. Core Structure and Configuration Advantages

The equipment adopts a modular frame design, and the whole machine is light and compact (external dimensions 500×400×1250mm, weight about 250kg), supporting both vertical and horizontal installation methods, which is convenient for maintenance and cleaning. The core components take into account stability and flexibility:

The clamping device is equipped with pneumatic claws and manual adjustment brackets, which can adapt to workpieces of different lengths and shapes, ensuring that the workpieces are fixed firmly during the welding process;

The cross slide assembly adopts double-row precision linear guides and stepper/servo motor drive, with an axial and radial electric control displacement of ±40mm. It has outstanding motion stability and rigidity, and supports arc length automatic tracking and weld摆动 forming (weld oscillation forming);

The wire feeder has an adjustable wire feeding speed range of 80~1000mm/min, is compatible with various wire diameters of 0.8-2.4mm, is suitable for materials such as carbon steel, stainless steel, and aluminum alloy, and has large wire feeding force and convenient operation;

The 300A water-cooled TIG welding torch adopts a forced water cooling design, with a high duty cycle and long service life. It is matched with the Panasonic YC-400TX digital welding power source, and the maximum welding current can reach 300A, ensuring the reliability of long-term continuous welding.

The key components of the equipment are all selected from well-known brands. The PLC adopts Mitsubishi/Xinje products, the electrical components are from Omron and Schneider, and the wires and cables are selected from Qifan and Misumi, etc., ensuring the stable operation of the equipment from the source.

III. Intelligent Control and Operational Convenience

The MHW50 welding machine is equipped with the MH-P02 highly integrated welding control system, integrating dual control centers of PLC and CPU, supporting linkage or separate control, and the main control program can be upgraded and expanded. It is equipped with a 10-inch color touch screen operation console and remote control center, and the operation interface is user-friendly, reducing the operation threshold for personnel.

The control system is powerful, with 8 interval partitions and 80 parameter storage functions. It can preset multi-stage parameters such as pre-gas feeding, pre-melting, and attenuation, and display data such as current, voltage, and linear speed in real time during the welding process. Its core control advantages include:

The rotation speed is adjustable from 0.5-10rpm, supporting forward and reverse rotation control;

The pulse current frequency is adjustable from 0.5~50Hz, realizing precise current control;

The swing control precision reaches ±0.1mm, and the edge dwell time can be adjusted independently;

It has multiple protection functions such as overvoltage, overcurrent, and leakage, and automatically alarms when arc ignition fails or the tungsten electrode is short-circuited.

In addition, the equipment supports the breakpoint memory function during welding power failure. During the welding process, the position of the welding torch and the wire feeding parameters can be fine-tuned, greatly improving the operation flexibility and welding success rate.

IV. Quality Assurance and Service Support

Shanghai Meihan Technology provides comprehensive quality assurance and technical services for the MHW50 welding machine. The equipment has a warranty period of 1 year (excluding consumables). During the warranty period, free technical support and component replacement are provided for faults caused by design and manufacturing reasons. According to user needs, the manufacturer provides free on-site training for 2-3 operators until they reach the independent production capacity.

With its precise welding performance, intelligent control design and reliable quality assurance, the MHW50 automatic oil pipe circumferential seam welding machine perfectly meets the "efficient, precise and flexible" welding needs in industrial production, providing strong support for oil pipe manufacturing enterprises to improve production efficiency and reduce costs, and has become an ideal choice for modern industrial oil pipe welding.