"Wearing thick clothes in summer to prevent scalds, scars as standard, and prone to lumbar disc herniation after long-term work" – this is the real daily life of welders. It's said that welding is a "lucrative" job, but behind the high salary lies the attack of high temperature, molten iron and smoke, as well as high dependence on experience. Nowadays, the emergence of Meihan automatic welding equipment is completely changing this situation: with it, welders no longer have to bear the hardship of "trading health for income".

Manual welding pain points, solved one by one by Meihan

The hardships of welders are exactly where Meihan's full-automatic TIG welding equipment focuses its efforts:

In summer heat, welders dare not expose their skin for fear of blisters caused by splashing molten iron. However, Meihan's full-automatic TIG welding equipment uses cylinders and profiling to clamp the welding torch, enabling fully automated operation. Workers only need to set parameters and monitor the equipment in the safe area. Risks from molten iron and arc light are isolated, so there's no need to wrap up tightly anymore.

Where the construction site is, that's our welding workplace (safe)

More importantly, in terms of health protection: smoke and arc light can cause blurred vision, and long-term holding of welding torches can easily lead to lumbar disc herniation. Meihan's dual gas circuit design can dredge smoke, four-channel argon protection improves weld quality and makes welds more beautiful. The closed welding torch head prevents arc light leakage, and the water-cooled base plate supports long-time operation of the equipment. Workers don't need to maintain a fixed posture, reducing the hidden danger of occupational diseases from the source.

No reliance on welding experience, bid farewell to "manual dependence"

"Welding is easy to get started, but becoming a master depends on accumulation over time" – this is the limitation of manual welding. However, Meihan automatic welding equipment is equipped with "one-click operation + expert parameter system", which completely breaks this logic: without welders spending years practicing techniques, just input the pipe diameter and wall thickness to be welded, and the system will automatically generate expert welding parameters. Whether it's stainless steel pipes, carbon steel pipes or other alloy pipe welding, elbow, tee, flange seat, sleeve welding, etc., Meihan automatic welding equipment always has a model that can accurately solve your welding needs.

Let "leftward welding" and "rightward welding" become a thing of the past, one hole per minute, yeah...

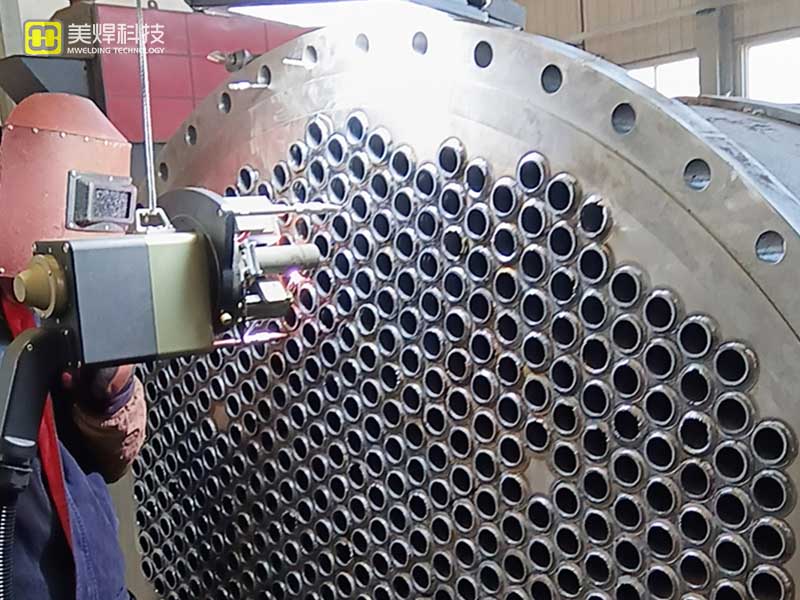

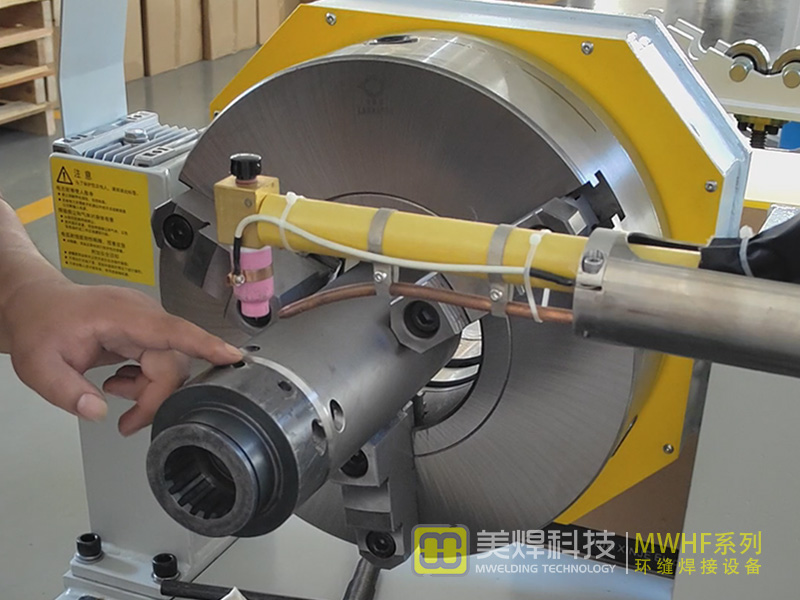

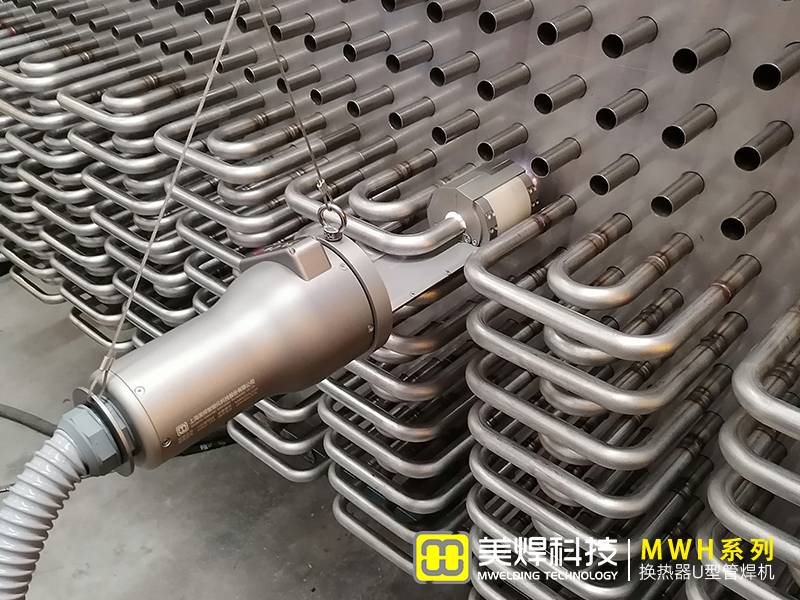

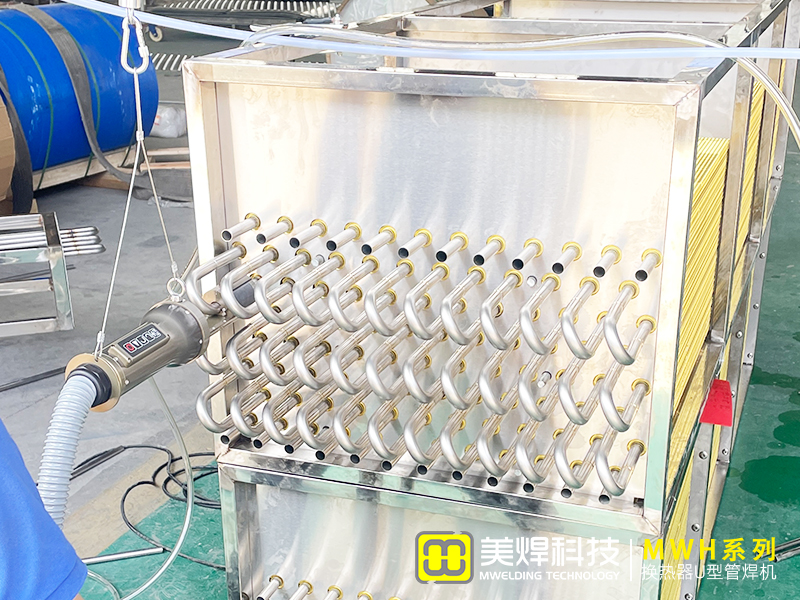

For welding U-shaped dense tubes of heat exchangers, use Meihan's U-tube welding machine; for thin-walled stainless steel clean pipes and water treatment pipes, use Meihan's closed pipe welding machine MWF series; for welding medium and thick-walled petrochemical pipes (up to 25mm wall thickness), use open pipe welding equipment MWG series; for boiler, refrigeration, heat exchanger, pressure vessel and other industries, use Meihan all-position tube-sheet welding machine, a perfect solution for dense honeycomb hole welding; we also have customized circumferential welding machines, plasma welding systems, surfacing equipment, and more sophisticated TIG welding robots...

The welds are beautiful, no manual intervention is needed, the operation is simple, and more stable than senior welders. Problems such as "incomplete penetration" and "burn-through" are 100% eliminated, no longer relying on welders' "feel" and "eyesight".

It's not eliminating welders, but making welders more dignified

Saying goodbye to complex welding environments, some people worry that equipment will make welders unemployed, but this is not the case: it eliminates the traditional mode of "trading physical strength for output". In the past, welders had to work hard in dangerous environments; now, workers can operate welding equipment after simple training, transforming from "hard operators" to "equipment monitors", no longer worrying about health risks, nor relying on experience to "gamble" on quality.

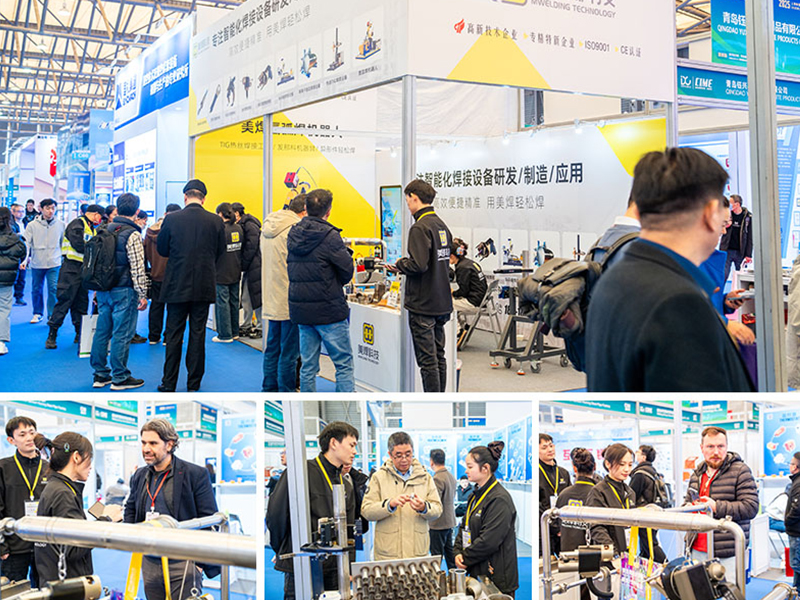

Meihan automatic welding equipment makes "lucrative" welding no longer "unbearable". If you have welders around you who are persisting with difficulty, you might as well tell them: welding is no longer a helpless choice with "scars all over the body". Meihan is making this industry safer and more dignified. To learn more about equipment knowledge and bid farewell to the hardships of traditional welding, welcome to pay attention to us.